Video

Product Description

The automatic feeder can be set to feed a certain number of screws at a time, allowing for greater speed and accuracy in assembly. The machine can also be programmed to move the screws around so they are in the correct position for insertion,This eliminates the need to manually position the screws and makes assembly much faster.

Features

♦ Optimized screw feeder comes with useful counting function

♦ Digital display, simple and elegant design

♦ Setting feeding screws within 0-999,stop feeding automatically once mission complete

♦ The quantity of feeded screw will be recorded for the user's reference

♦ Automatic and manual switch to chose from to counting function

♦ Inherit the advantages of common screw supplier, much stable function never block screw again, and adjustable orbit, simple operation same as the common screw feeder.

♦ Stable performance,no screws stucking,feeding track adjustable

♦ Suitable screws dia from 1-5mm, and resizable

No screws stucking

Screws that is not delivered to the track would roll back to the roller for the next delivery. Feeding speed could be regulated by adjusting the vibration strength.

Malfunction alarming

Screw feeding and vibration controlled separately,it is free to set delay and stop time,once malfunction happens, alarm will be given.

Product Parameters

| Parameters | |

| Fit screws | M1.0-M5.0(Max L=20mm) |

| Feeding speed: | 2 screws/s |

| Input voltage: | DC 15V/1500mA |

| Dimension: | L180mm*W125mm*H150mm |

| Weight: | 2.5KG |

| Parameters | |

| Fit screws | M1.0-M5.0(Max L=20mm) |

| Feeding speed: | 2 screws/s |

| Input voltage: | DC 15V/1500mA |

| Dimension: | L180mm*W125mm*H150mm |

| Weight: | 2.5KG |

| Accessories |

| Manual book |

| DC power supply(input 180-220V,output DC15V) |

| Hexagonal spanner |

Product Details

|

item

|

value

|

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

MINGSHUO

|

|

Condition

|

New

|

|

Weight (KG)

|

400

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Motor, Gear

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Other

|

|

Showroom Location

|

None

|

|

Type

|

Customized

|

|

Product name

|

Wire weiding machiine

|

|

Voltage

|

AC 110V/220V,50Hz/60Hz

|

|

Feature

|

High Precision

|

|

Application

|

Automation Equipment

|

| Item | Description | Content |

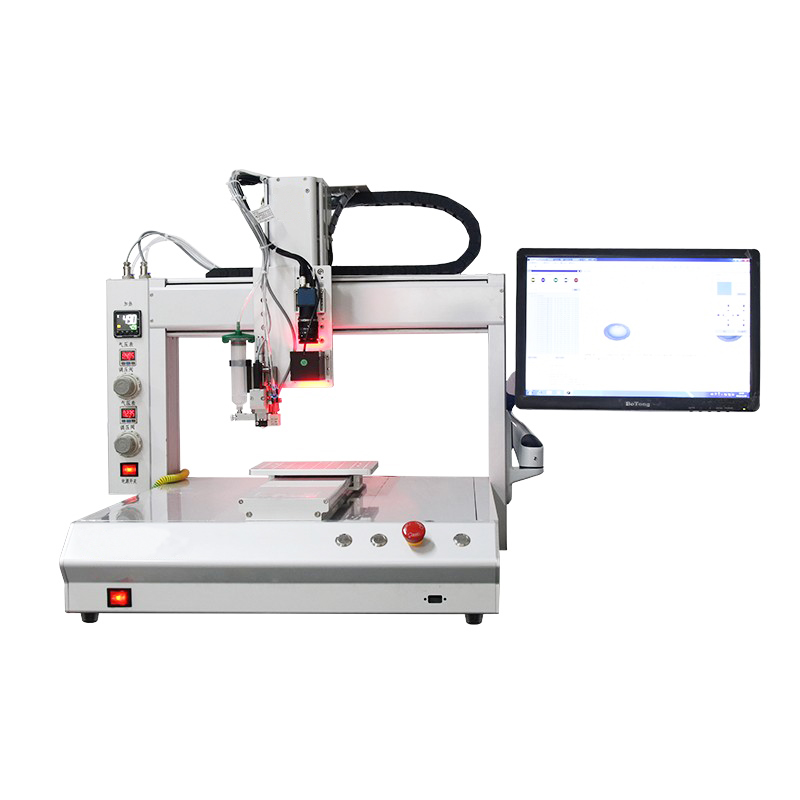

| 1 | Equipment Function | a. Roll wire, automatic feeding. b. Equipment automatic cutting, peeling, tinning, tin dipping, and automatic soldering(Welding of 1-4 wires is optional). c. Can achieve free switching of 4-color wires. d. Single direction welding, multi angle welding (Optional). e. After welding, the inclination angle of the wire is 0-25 °. |

| 2 | Production capacity and defects | Approximately 3000~4000 wires welded per hour. |

| 3 | PCBA board size requirements | Can be used within the range of 166-210mm. |

| 4 | Requirements for components around the solder board | a. Component height: Within the 1mm range of the solder board, no components higher than 2.6mm are allowed (Except for special circumstances). b. PCB board size: 1.5-3mm. c. PCB board position: All within the PCB range (Except for special circumstances) |

| 5 | Peeling distance | 1. Shortest peeling wire: 13mm. 2. Maximum peeling length: 170mm. 3. Peeling length: 2-4mm wire skin. |

Equipment advantages:

1. Strong universality of equipment: almost all products that meet the travel requirements for wire peeling and cutting, as well as those without dryness during welding, can be universally used.

2. The processed products have high consistency: cutting, peeling, and welding are all automatically completed by the equipment, and the length of wire and the fullness of solder joints between products will be the same.

3. Labor saving: Operator can assist in loading and unloading materials on a regular basis, with one person being able to take care of 2 to 3 equipment, without the need for skilled welding workers. Ordinary employees can watch the machine.

4. High efficiency: A medium configuration equipment with two simultaneous welding lines can weld 2100 wires per hour. High configuration equipment with four simultaneous welding lines can weld 3600 wires per hour.