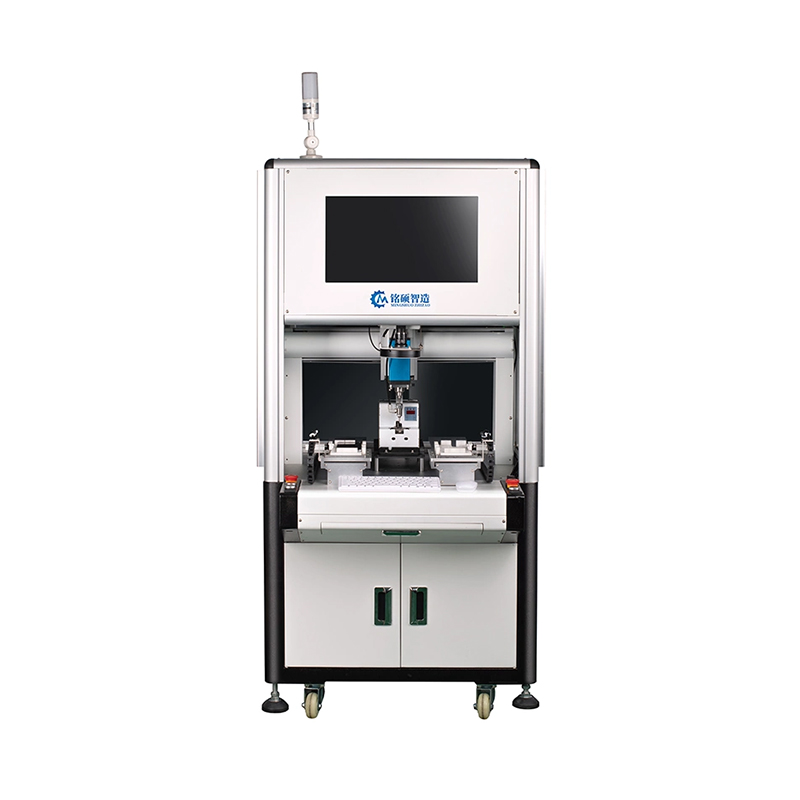

Product Description

They can perform a range of operations including turning, threading, drilling and tapping. Screw machines are often equipped with multiple spindles that can process multiple parts at the same time, thereby increasing productivity.

There are different types of screw machines, including single-axis and multi-axis machines. Single-axis screw machines are capable of producing smaller batches of parts and are more versatile in terms of the range of operations they can perform.

Video

Product Details

Functions

1. Wide universality, small in size, can cooperate with production line, convenient for product replacement.

2. With intelligent inspection function, inspection miss locked,unstable locked,loose screw and so on.

3. The Y axis can be made into double-station(that is, double Y axis),so the operator can load alternately.

4. High degree of automation, easy operation which the staff can master and debug quickly.

5. Accurate torsion, convenient adjustment, and the quality of lock is guaranteed.

6. Touch screen display or teach pendant programmable achieve more operations,Through a simple programming, can be put into production, convenient for production and management.

7. With the function of leak detection, once a screw did not fill in place it can fill continually or start alarm processing.

Applications

It is suitable for all kinds of screw fastening process on mobile phones, keyboards, monitors, car accessories, toys, small home electrical appliances, integrated circuits, printed circuit boards, LCD screen, electronic components (such as relays, speakers), etc.

Parameters

| Model | MS-PX-DS5441-SP |

| Feeder mode | Adsorption Type |

| Dimension (L*W*H) (mm) | 700*580*650mm |

| Weight(kg) | 45 KG |

| Operation Range (X*Y*Z) (mm) | 380*365*65mm |

| Axis | 4 Axis (X,Y1,Y2,Z) |

| Driving mode | Precision Stepping Motor+Timing belt |

| Maximum Speed | X,Y 600mm/S, Z 500mm/S |

| Repeated precision | X,Y,Z ±0.02mm |

| Teaching Method | Remote Teaching/Manual Data Input/Optional: LCD Touch Screen |

| Motor system | precision stepper motor |

| Transmission mode | Timing belt + screw rod +guide rail |

| Control Panel | Teach pendant (optional:PC or Touch Screen) |

| Torque Range | 0.5~15kgf.cm (can be adjusted ) |

| Tighten efficiency | About 60pcs/min(according to the screw type) |

| Voltage | AC 110V/220V,50Hz/60Hz |

| External Interface | USB + RS232 |

| Power Source | Electricity + Pneumatic |

| Air pressure requirement | 0.4 to 0.6MPa (4 to 6kg/cm2) as dry air |

| Working Temperature | 5-40C° |

| Working Humidity | 20-90% RH |

|

item

|

value

|

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

MINGSHUO

|

|

Condition

|

New

|

|

Weight (KG)

|

400

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Motor, Gear

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Other

|

|

Showroom Location

|

None

|

|

Type

|

Customized

|

|

Product name

|

Wire weiding machiine

|

|

Voltage

|

AC 110V/220V,50Hz/60Hz

|

|

Feature

|

High Precision

|

|

Application

|

Automation Equipment

|

| Item | Description | Content |

| 1 | Equipment Function | a. Roll wire, automatic feeding. b. Equipment automatic cutting, peeling, tinning, tin dipping, and automatic soldering(Welding of 1-4 wires is optional). c. Can achieve free switching of 4-color wires. d. Single direction welding, multi angle welding (Optional). e. After welding, the inclination angle of the wire is 0-25 °. |

| 2 | Production capacity and defects | Approximately 3000~4000 wires welded per hour. |

| 3 | PCBA board size requirements | Can be used within the range of 166-210mm. |

| 4 | Requirements for components around the solder board | a. Component height: Within the 1mm range of the solder board, no components higher than 2.6mm are allowed (Except for special circumstances). b. PCB board size: 1.5-3mm. c. PCB board position: All within the PCB range (Except for special circumstances) |

| 5 | Peeling distance | 1. Shortest peeling wire: 13mm. 2. Maximum peeling length: 170mm. 3. Peeling length: 2-4mm wire skin. |

Equipment advantages:

1. Strong universality of equipment: almost all products that meet the travel requirements for wire peeling and cutting, as well as those without dryness during welding, can be universally used.

2. The processed products have high consistency: cutting, peeling, and welding are all automatically completed by the equipment, and the length of wire and the fullness of solder joints between products will be the same.

3. Labor saving: Operator can assist in loading and unloading materials on a regular basis, with one person being able to take care of 2 to 3 equipment, without the need for skilled welding workers. Ordinary employees can watch the machine.

4. High efficiency: A medium configuration equipment with two simultaneous welding lines can weld 2100 wires per hour. High configuration equipment with four simultaneous welding lines can weld 3600 wires per hour.